How to avoid pen barrel blowouts

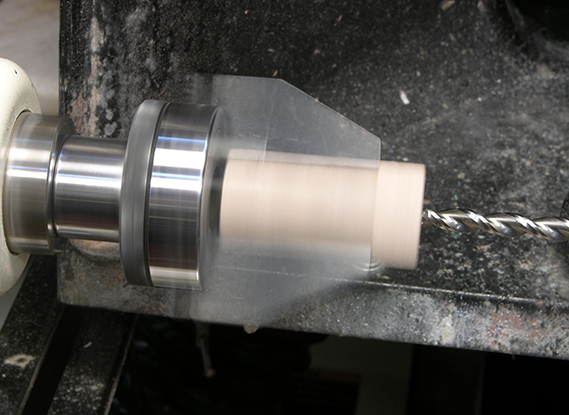

“How to avoid pen barrel blowouts” By Barry Gross This happens to the best of us and if someone says that it never happens to them they are not telling you the truth! Blows out can come from a number of reasons but the two things I look at are how was the pen blank drilled and then how was the pen tube glued into the pen blank? Let’s first look at drilling the pen blank. I do not drill with a drill press. I drill on the lathe (Item #CSCPENCHK) – I believe you get a more accurate straight holes drilling on the lathe. If the hole is too loose, then the glue you use may not make good contact between the pen tube and the inside of the pen blank. If the glue is not making a bond and you get a catch then you might tear a piece of the blank off. |

|

|

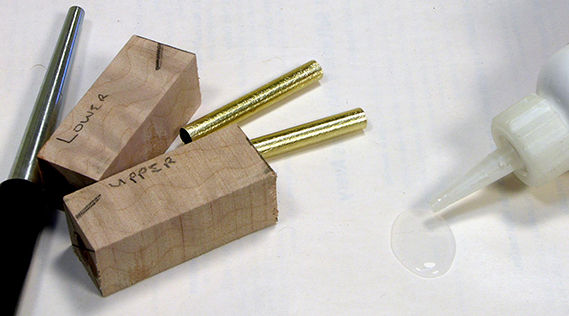

The next culprit may be the pen tubes were not roughed up – I always rough up the pen tubes so the glue has a better surface to have the glue bond to it. The tube on the right is not roughed up while the tube on the left is roughed up and is ready to be glued into the pen blank. |

|

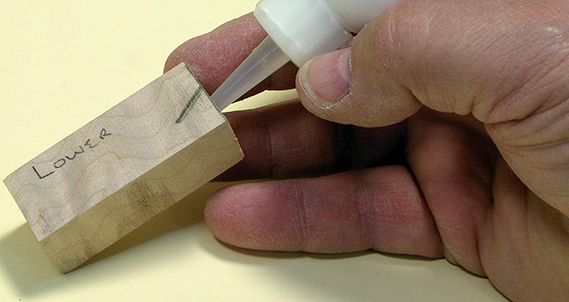

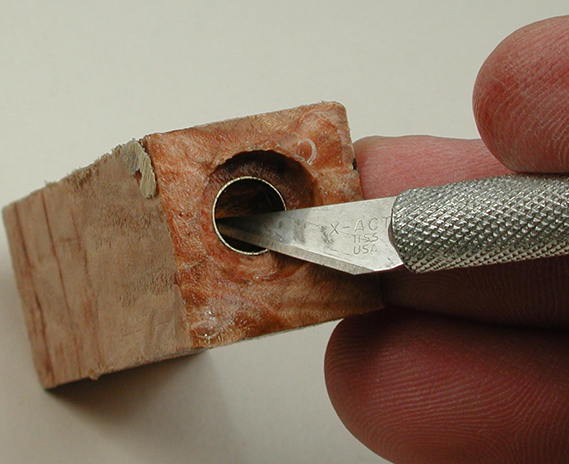

If the pen blank you are using is not stabilized, then drip some thin CA glue into the pen blank so it can be absorbed into the wood and this will allow for a better surface for the CA glue to bond with.  Next I will use some CA glue to glue the pen tubes into the pen blank. If you happen to get some glue on the inside of the tube, use an exacto knife to remove the excess glue. If you follow these guidelines, it might help you have a few less “blow outs” with your turnings and having more success is a lot more fun than trying to pick up the pieces! |