Working with Blanks

| Dense woods and stabilized (plastic-infused) wood blanks can be brittle and prone to blowout during drilling. To avoid that from happening cut your blanks 3/8" longer than the brass tube. Then, using the depth stop on a drill press, drill a hole 1/8" deeper than the length of the tube. The wood left at the bottom of the hole will help keep the blank together. Finally, cut the blank to the length of the tube by trimming off the excess. |

|

| Cyanoacrylate (instant) glue works great for gluing brass tubes inside pen blanks because it sets up in seconds. But it can set up too quick, before you have the tube in the proper position. That's because moisture in wood speed the glue's curing. Heat also accelerates curing. To give yourself more time to correctly position the tube, place blanks in the refrigerator one hour before gluing. |

|

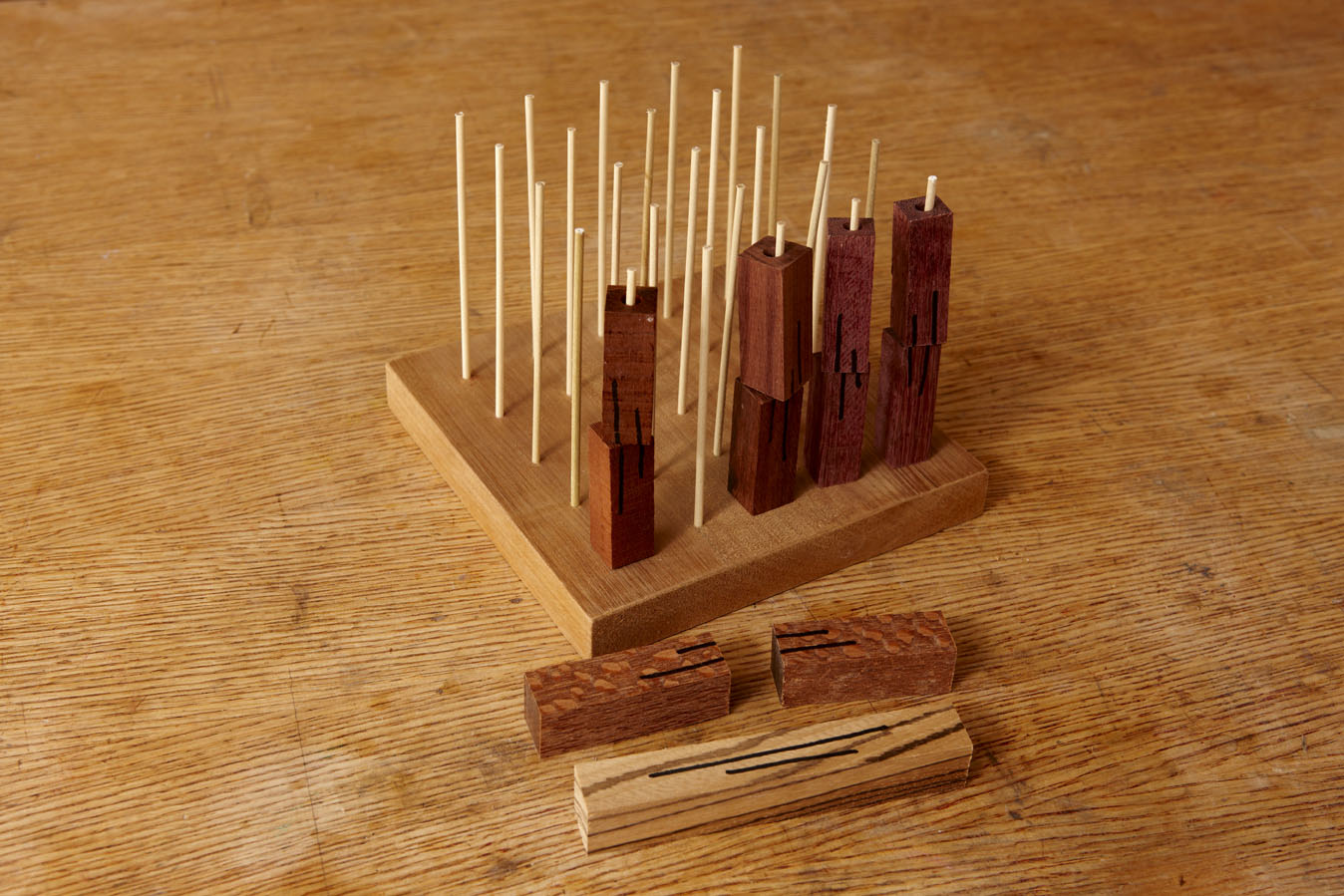

| To get the best finished look from your pen blanks, mark them so you can easily align their grain patterns after cutting them in half and drilling the holes. Then, build this simple stand to keep the pen halves organized. First, cut a 7 x 7" piece of scrap wood. Then, drill five rows of 1/8" holes, 1/2" deep, with each row having five more holes for 25 total. Glue 5" lengths of 1/8" dowel rod into each hole. You can now keep up to 25 blanks organized and easy to inspect. |

|

|

|

It's easy to create a beautiful stabilized wood blank pen by following these easy steps. First, turn the blanks using the same well-sharpened turning tools you use for any regular hardwood. Next, polish using 1200 grit sandpaper or try our 4 Piece Stablized Wood Finishing kit (

It's easy to create a beautiful stabilized wood blank pen by following these easy steps. First, turn the blanks using the same well-sharpened turning tools you use for any regular hardwood. Next, polish using 1200 grit sandpaper or try our 4 Piece Stablized Wood Finishing kit (