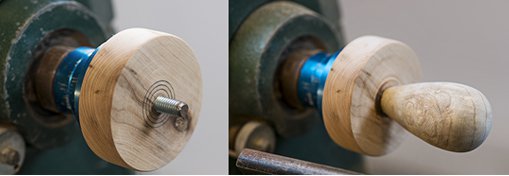

When turning bottle stoppers and other projects where the outside diameter of the wood to the mating metal part is important for a flush fit and you don’t have an existing chuck with the necessary diameter, washers make an inexpensive and reusable guide. For example, when turning the bottle stopper shown, the end that mates with the chrome stopper looks and feels best when the surfaces are perfectly flush. To accomplish this, file or grind one or two washers to the same diameter as the mating section of the chrome stopper. Slide the washers over the threaded mandrel. Then, turn and sand the stopper bottom end to same outside diameter as the washers. Not only do the washers provide an exact diameter guide, but they allow clearance to turn and sand the stopper’s bottom end without turning into the auxiliary wood faceplate.

Similar Posts

Make an Inexpensive Threaded Headstock

To create your own threaded headstock, mount a piece of hardwood at least 1″ thick to your metal faceplate. Turn…

How to Make a Watch Parts Pen Blank By Barry Gross

I chose to make this watch parts blank paired with Penn State Industries new Steampump Pen Kit as a really great Steampunk…

How to Choose the Best-Looking Grain

After ripping your own pen-blank stock square, you don’t necessarily want to start cross cutting from an end of the…

Sand this way and that

All pen barrels have to be sanded smooth, but how you do that sanding can make a big difference in…

How to stop splatter

If you’ve ever visited another woodturner’s shop, nine times out of 10 the area behind the lathe is a disaster…

How to use a potato to keep glue in its place

Glue has a tendency to get on the inside of brass tubes when gluing them in blanks. That excess glue…