To create your own threaded headstock, mount a piece of hardwood at least 1″ thick to your metal faceplate. Turn the stock round and use a pencil to mark concentric rings until you’ve found dead center of the auxiliary faceplate. Drill an 11/32” hole 1” deep into the auxiliary faceplate. Epoxy a 3/8″ x 2 1/2″ bolt or 3/8″ threaded rod 2″ long, into the hole and let the epoxy cure. Once the epoxy has totally hardened, use a hacksaw to cut the head of the bolt off so just the threading is exposed. Turn the lathe on and use a file to to create a slight chamfer on the end of the threaded rod. Then thread the workpiece onto the exposed threaded end

Similar Posts

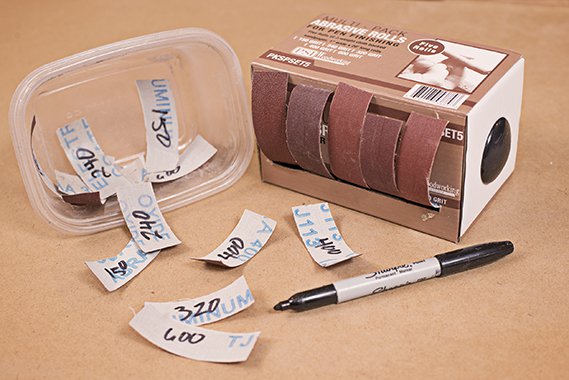

Quit Guessing Grits

Unlike sheet abrasives, abrasive strips don’t have the grits marked on the back side, making it easy to lose track…

How to cut your pen blank with a table saw sled thin-kerf blade combination

If the table saw is your choice for cross cutting pen stock to length, consider this table saw sled and…

Cast Your Own Pen Blanks to Make Beautiful Resin Pens

Use our versitile Cast-a-kit for making your own unique, customized pen blanks. By Barry Gross – “Mr. Solid Surface” Let Your…

Know Your Viscosity at a Glance

With numerous bottles of cyanoacrylate in the shop and aging eyes, it’s easy to grab the wrong bottle for the…

How to Choose the Best-Looking Grain

After ripping your own pen-blank stock square, you don’t necessarily want to start cross cutting from an end of the…

How to make a Cabochon inlay

Use s small piece of contrasting scrap wood, plastic or Corian™ to make a unique Cabochon insert that adds interest…