When turning bottle stoppers, bottle openers, and other projects where you want a specific diameter from one project to the next, an open-ended wrench is the perfect tool to use as a caliper. To determine the diameter needed for the turning, select a wrench with an opening size to match the needed diameter, and use it as a quick measuring tool when turning the project to shape. Or, if the wrench is too thick, transfer the opening size to a thin piece of stock, and cut it to size, and use that as a caliper. For example, when turning bottle stoppers, find a wrench whose opening measures the end of the chrome stopper that mates with the turned wood piece. Then, when turning the wood part of the stopper to shape, use the wrench or wood caliper to check the diameter of the turning until it is the desired diameter. When the turning reaches the necessary diameter, the tool will slip over the turning. This tip also works well when turning tenons to a particular diameter to fit into a mating mortise.

Similar Posts

How to Choose the Best-Looking Grain

After ripping your own pen-blank stock square, you don’t necessarily want to start cross cutting from an end of the…

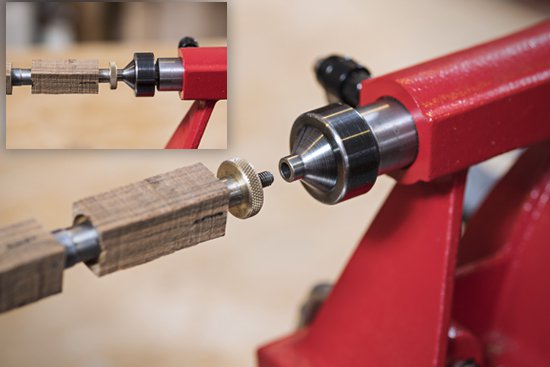

How to stop bending your mandrel

Instructions often state, “don’t over tighten the tailstock when mounting the pen mandrel between centers.” Problem is you don’t know…

An Easy Way to Take Measurements at Your Lathe

We often need to take measurements at the lathe. Rather than constantly worrying about carrying a tape measure, simply use…

How to make a Cabochon inlay

Use s small piece of contrasting scrap wood, plastic or Corian™ to make a unique Cabochon insert that adds interest…

How to cut your pen blank with a table saw sled thin-kerf blade combination

If the table saw is your choice for cross cutting pen stock to length, consider this table saw sled and…

Know Your Viscosity at a Glance

With numerous bottles of cyanoacrylate in the shop and aging eyes, it’s easy to grab the wrong bottle for the…