If the table saw is your choice for cross cutting pen stock to length, consider this table saw sled and thin-kerf blade combination. The sled base, cut from ½” baltic birch plywood, measures 6×16”. The support, cut from the same material, to which the hold down clamp is screwed to measures 4×16” and is glued to the base with the back edges flush. As a safety indicator, consider painting a red “caution area” where the blade enters the support. The distance from the clamped-down stop to the inside edge of the blade is determined by the length of the brass pen barrels you’ll be using. To cap it off, use a thin-kerf blade for cross cutting the stock, which minimizes the stock lost to the kerf, allowing the grain in the two matching blanks to match up better for the final product.

Similar Posts

How to make a Cabochon inlay

Use s small piece of contrasting scrap wood, plastic or Corian™ to make a unique Cabochon insert that adds interest…

Barry Gross’s Techniques for Making an Acrylic pen

Part 1 – Preparation: In Part 1, Barry shows you tips & techniques for marking up and cutting the pen…

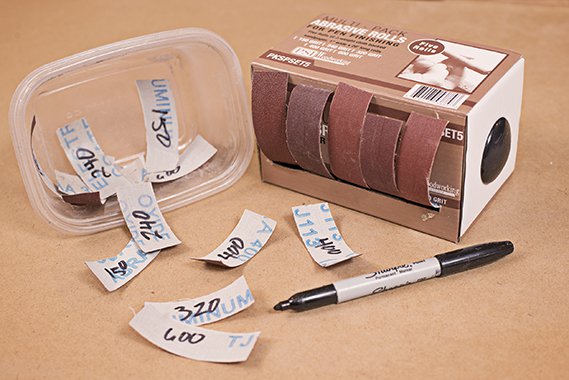

Quit Guessing Grits

Unlike sheet abrasives, abrasive strips don’t have the grits marked on the back side, making it easy to lose track…

7 Steps to making a Pool Cue Kit on your Midi Lathe

A lathe with a minimum of 32” Bed. Turning tools: Spindle Gouge, parting tool and 1” skew essential. The Turning…

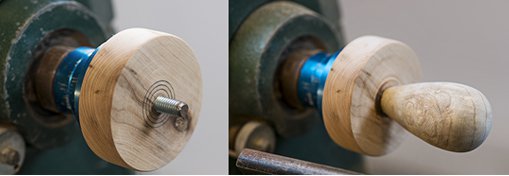

Make an Inexpensive Threaded Headstock

To create your own threaded headstock, mount a piece of hardwood at least 1″ thick to your metal faceplate. Turn…

Sand this way and that

All pen barrels have to be sanded smooth, but how you do that sanding can make a big difference in…